UOP and BASF create new butadiene purification and recovery process

Managing Editor, Hydrocarbon Online

UOP LLC and BASF Aktiengesellschaft recently announced the availability of a new process to recover high-purity 1,3-butadiene from crude C4 streams found in ethylene plants.

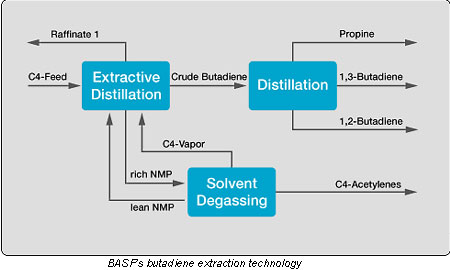

The process combines UOP's KLP technology with BASF's butadiene extraction technology to selectively hydrogenate the C4 acetylenes and then recover 1,3-butadiene from the butanes and butenes.

The new integrated process provides several advantages over traditional two-stage extraction processes. Operating companies will achieve high butadiene purity, higher butadiene recovery, lower utility costs, lower maintenance costs and improved operating safety with the new process. There is also less equipment required in the new integrated process, which results in a lower capital investment cost compared to traditional processes.

UOP's KLP acetylene removal technology for C4 acetylenes has been commercially operating since 1984. There are eight licensees worldwide, and most use the approach of hydrogenating the acetylenes prior to extraction.

BASF's butadiene extraction technology has been commercially available since 1968. It employs N-methylpyrrolidone as the solvent. There are approximately 25 licensees worldwide. It is one of the most widespread petrochemical technologies in use today.

For more information, contact Sue Zillman, UOP, Phone: 847-391-2682, e-mail sezillma@uop.com